How To Build A Beginner's Maple Syrup Evaporator

Alan Garbers shares how he built an inexpensive, but highly productive maple syrup evaporator

As demand grows the small producer may tap more and more trees to fill the need. It isn’t surprising that many backyard syrup producers quickly outgrow their boiling apparatus and turn to the commercial maple equipment catalogs.

Several years ago I had reached this same predicament and was dreaming of purchasing a real maple syrup evaporator. The evaporator I was looking at was a small back yard model that could handle 20 to 150 taps. Two things stopped me from spending the money. The first problem was the fact that a commercially made maple syrup evaporator cost a cool grand. The second problem was that on slow days the sap from the two dozen trees I tap would just barely cover the bottom of the large pan. That in turn would risk running the evap dry, scorching the pan, or worse, warping the metal and destroying it.

I dreamed of an evap that was low cost and could have variable capacity to match the varying sap flow. I wanted the pan to be of stainless steel so it would be easy to clean and wouldn’t rust in the off season. I wanted a firebox that I could build on-site with readily available materials.

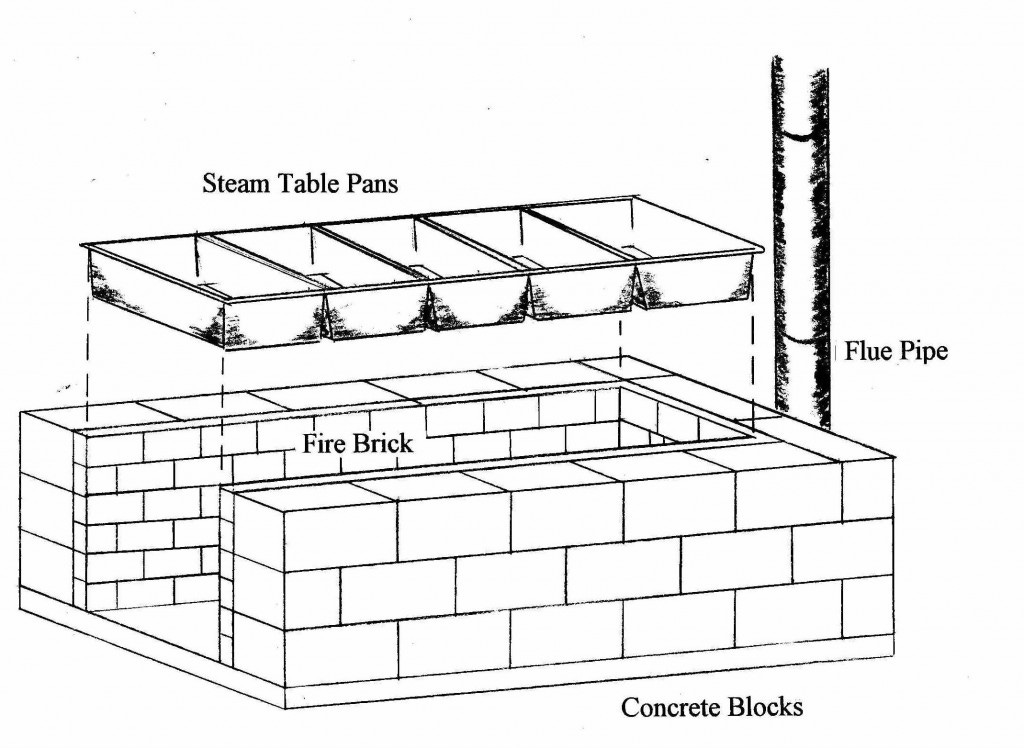

The design I came up with is the sum of these desires. For the firebox and pan support I chose the inexpensive cement block. I had quite a few stacked around our place that were leftovers from other projects. Irregular or slightly damaged blocks can also be had at many block companies for a fraction of the cost of new ones.

By using separate pans the capacity can vary by using water in some pans while sugar water is boiled down in others. The closer the pan is to the flue, the faster it boils. The closer the pan is to the door or inlet, the slower it boils.

For the boiling pans I wanted something that was cheap, would hold up well over the years, and be easy to replace if damaged. I found used steam table pans to be just the ticket. Steam table pans can be found at any used restaurant equipment dealer and at many scrap metal dealers. I was able to get my pans for $3.00 to $5.00 each.

Before I started work building my evap I made a mock up with the blocks and fire brick to figure out my dimensions. A mock up is made by placing the blocks and brick as they would be on the completed walls. Keep in mind dimensions will be greater once a half inch of mortar is added between the blocks. Drawing it out on paper can also help figure the dimensions. In my design I wanted the steam table pans to set down into the block walls, with the pan lips being supported by the fire brick liner. This meant the interior width had to be 20 inches.

To lay the foundation for the evap a solid concrete slab is desired. As my old shed has a dirt floor, I knocked together some 2” by 4” lumber into forms for the shape and dimensions I wanted for my finished evap. If you’re not familiar with masonry work you might want to enlist the aid of an experienced friend to help you. The promise of pure, homemade maple syrup can help the recruitment.

Since the foundation is going to be supporting a tremendous amount of weight I scraped away all of the loose fill and debris so that nothing would settle later on. As wet concrete is heavy and has a tendency to bulge or move forms, stakes were driven a intervals and nailed to the forms. To add even more strength, place reinforcement mesh, used in driveways, inside the proposed foundation.

When the form is ready, pick a warm day to pour the cement. In many areas tool rental companies provide premixed concrete ready to pour in special one square yard trailers. In most cases it is best to call ahead to make sure the mixer is working and trailers are still available. Trowels, floats and other concrete working tools can rented at the same time. Since your evap foundation probably won’t take anywhere near a full yard of concrete it might also be wise to have other small concrete jobs lined up to use the remainder. In example: my slab was 40” wide by 87” long by 4”deep. That figures out to be 13,920 cubic inches of concrete. One cubic foot of concrete is 1,728 cubic inches. 13,920 divided by 1,728 equals a little more than eight cubic feet. A cubic yard has 27 cubic feet so you can see how much extra can be available to do things like sidewalks, garage aprons, and basketball courts.

If the evaporator site isn’t in a location that the concrete trailer can be pulled up to, wheel barrows can be used to transport the concrete but speed is of the essence for the concrete sets up within a couple of hours, in your forms…in the wheel barrow…and in the trailer.

The forms can be removed a day later but the concrete should be fully cured before placing any weight on it. In cold weather this make take up to a week.

The foundation is done.

The next step it to build the pan bearing walls of the firebox. Using the concrete blocks, erect the U-shaped walls in another mock-up. Remember to install a section of stove pipe in the end for the flue. Working out any last minute problems can save headaches later. Once the mock-up is satisfactory, remove the blocks, carefully stacking them in the reverse order that they went on. By doing so, you will know exactly which block went where.

Using regular mortar, erect the walls as they were during the mock-up. Keep the walls square and straight. Failure to do so can cause problems later.

The walls start going up.

While the firebox could be used without firebrick, the concrete blocks would soon crack and break and all your hard work would eventually come crumbling down. Fire bricks are special heat-resistant bricks that insulate the concrete and prevent flame impingement. By using firebrick the firebox life can be extended indefinitely. Like concrete blocks, regular mortar will not hold up to the heat and flames so special firebrick mortar or epoxy is used. This special compound can be found at almost any brick supplier for $15 to $20 per can. While this is a high price the firebrick mortar is spread thin and goes a long way.

Plan your firebrick courses out a head of time so that it comes flush with the top of the concrete blocks. Prudent cutting with a brick chisel and careful planning of rows will make the job much easier.

Fire brick lines the inside walls to protect the concrete blocks. Creative layouts help assure that the tops of the firebrick and block line up.

The flue base needs to be strong enough to support whatever type of flue you chose.

I added an angle iron frame to hold the pans. This allowed me to grab the pan flanges easier and kept the pans from abrading the fire brick as I worked with them.

Once the fire box is complete a door can be made. While a door isn’t necessary it does help control the fire and boiling process. Whether leaning against the opening, or having it hinged and anchored to the concrete blocks, a piece of ¼” plate steel makes a good door. Old doors of wood fired boilers can also be used.

An additional step that can extend the life of the fire box is to add angle iron pan holders. Using a pan rack, the pans never come in contact with the fire brick, which can loosen them.

Final Costs

Commercial hobby evaporator 50-150 tap capacity $995.00

Home built evaporator Variable capacity $218.80

Slab concrete (cu. yard) 1/3 @ $65.00 $22.00

Concrete blocks 40 @ $ 1.27 $50.80

Firebrick 120 @ $ 0.80 $96.00

Mortar (50lb. Bag) 1 @ $ 5.00 $ 5.00

Firebrick mortar (can) 1 @ $15.00 $15.00

Pans 6 @ $ 5.00 $30.00

Total $218.80

When syrup season comes, place all of the pans in the racks and fill them with sap. Resist the urge to build a fire before filling the pans. It just takes a matter of seconds to warp or scorch a pan.

If there isn’t enough sap to fill all of the pans, simply fill what pans you can with sap, and fill the remaining pans with water. As the sap boils down transfer the sap from the low pan into the other sap pans to keep their level high. As each sap pan is emptied fill it with water to keep it from burning. When the final pan is low transfer the sap/syrup into a finishing pan and complete the boiling on a stove that can be easily controlled. WARNING: DON’T DUMP WATER INTO THE FIRE TO PUT IT OUT! Doing so will create clouds of billowing steam which WILL scorch and exposed skin, and might damage the firebrick walls

With proper care this inexpensive evaporator can last for generations and be the center piece of a memorable family tradition. Sugaring can involve the whole family. Tending the evap fire is a great way to relax and spend time with loved ones. The billowing clouds rising off the boiling sap are mesmerizing and old-timers swear nothing cures colds better than sap steam!

If your needs grow, this evap can assist you in keeping your initial costs low until you are ready to make the transition to a 1000 to 2000 tap high-efficiency commercial evaporator.

Whichever path you choose I know you will enjoy “sugaring” and it will be a occupation that will bring sweet success for many generations.